Leadership, competitiveness, fashion and high value

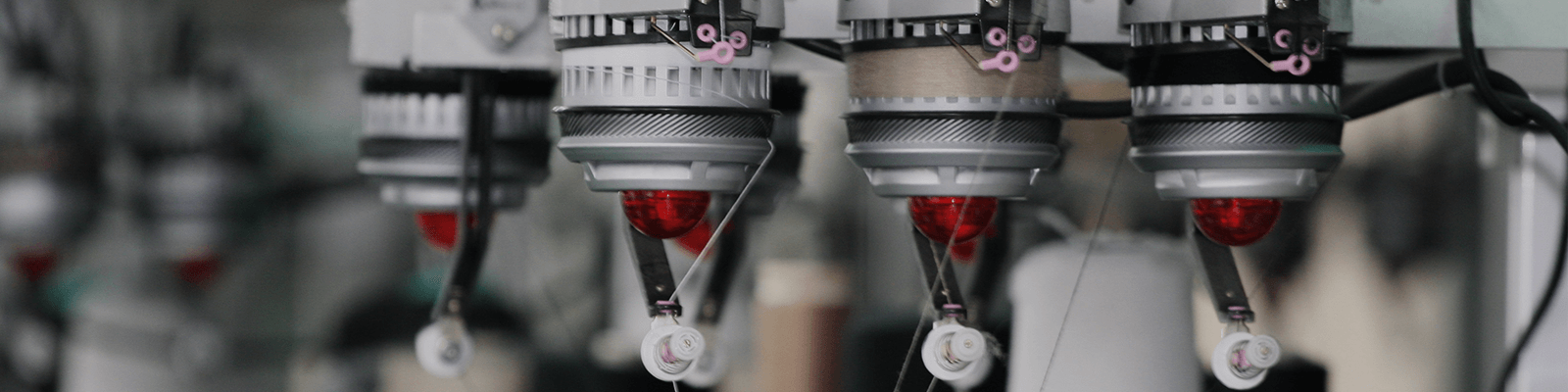

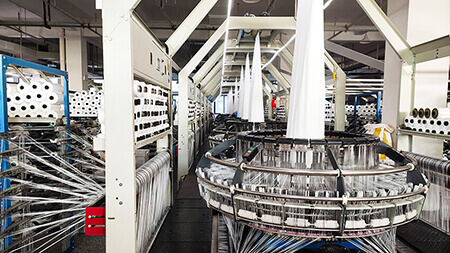

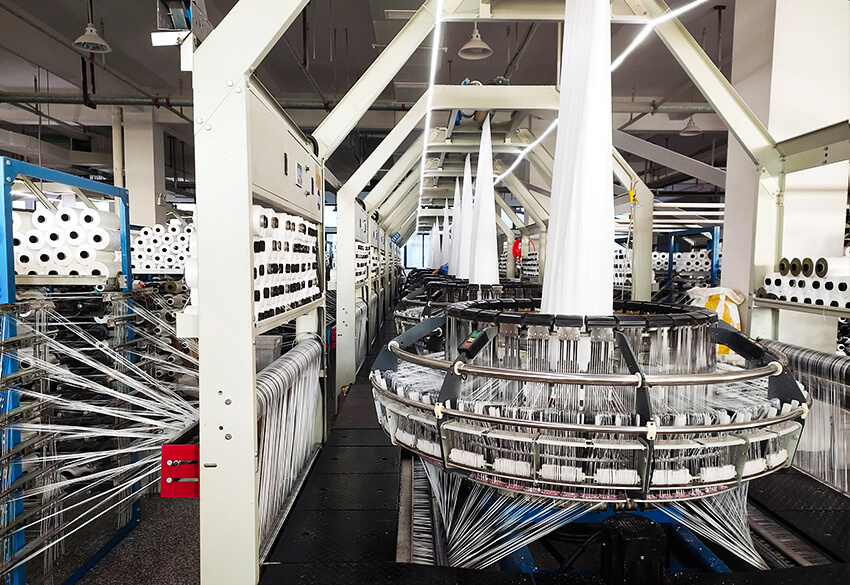

R & D innovation is a powerful weapon for Chende packaging to deal with market competition. The company invested 20 million yuan to eliminate and upgrade the core equipment,

it has 4 wire drawing production lines, 186 circular weaving production lines, 21 gravure color printing production lines (including 13 sets of more than 7 colors), 7 composite production lines

21 edging machines, 100 crimping machines, 13 full-automatic bagging, cutting and sewing machines, and supporting manual bagging personnel.

it has 4 wire drawing production lines, 186 circular weaving production lines, 21 gravure color printing production lines (including 13 sets of more than 7 colors), 7 composite production lines

21 edging machines, 100 crimping machines, 13 full-automatic bagging, cutting and sewing machines, and supporting manual bagging personnel.